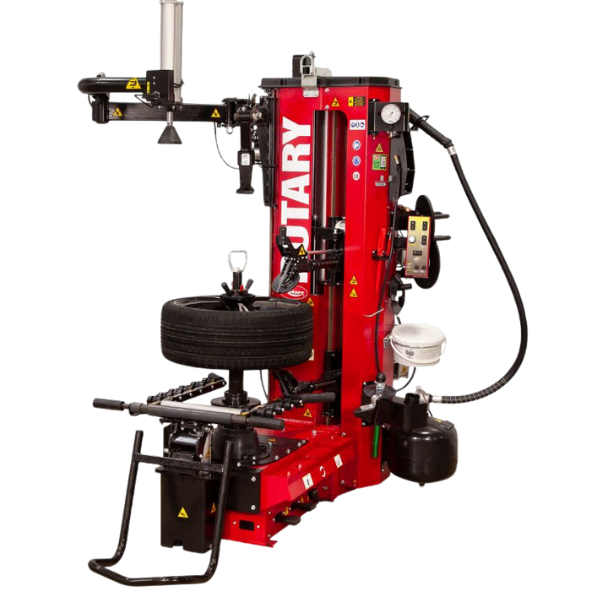

The Rotary R1250 Leverless Pro Premium Tire Changer is a top-tier tire changing machine designed to tackle the most demanding wheel and tire combinations with speed, safety, and precision. Built for versatility, this machine handles low-profile tires, run-flats, exotic rims, and light truck combinations like 17.5″ and 19″ wheels. The R1250’s fully leverless tire changer design, coupled with advanced features, ensures damage-free tire servicing while enhancing efficiency in your shop.

Key Features for Unmatched Performance:

- Center-Locking System: A three-position locking post accommodates standard and reverse-mount rims, offering unparalleled flexibility.

- Laser-Guided Tool Positioning: Ensures perfect roller placement for every operation, reducing errors and streamlining workflow.

- Simultaneous Dual Bead Rollers: Safely and accurately position rollers for faster match-mounting or bead-breaking.

- Patented Worry-Free Demounting: A polymer tool head prevents metal-to-metal contact, protecting both the tire and rim.

- Variable Speed Turntable Motor: The 0-15 RPM motor with an exclusive inverter adjusts speed to reduce stress on the bead, avoiding tire damage.

- Front-Loading Pneumatic Wheel Lift: Effortlessly positions heavy wheels with foot-pedal controls, minimizing operator fatigue.

- Top Bead Press Arm: A power-assisted depressor designed for mounting large or specialty tires.

Ease of Use:

The R1250 tire changer features a user-friendly design with foot pedal controls for inflation, rotation, and wheel lift operations. Its home function automatically moves tools to their starting position, while the memory feature saves setup locations, reducing errors and improving operational speed.

Standard Features:

- Integrated wheel lift

- Quick-lock rim clamping device with cone guard

- Power-assisted bead mount/demount tool

- Rotating pneumatic top bead pressing tool

- Storage cabinet

- Inflation station

- Tire paste lubricant and brush

Standard Equipment Includes:

- Chrome Clad Adapter for delicate finishes

- Traction Knife for precise bead placement

- Lube with Long-Handle Brush for efficient application

- 3/4 Ton Cone for heavy-duty operations

- Storage Cabinet for tool organization

Technical Specifications:

- Clamping Range: 10″-30″

- Maximum Tire Width: 19″

- Maximum Tire Diameter: 47″

- Bead-Breaking Force: 2,645 ft/lbs per roller

- Wheel Lift Capacity: 178 lbs

- Power Supply: 220V, 60Hz, single-phase

- Air Supply: 115-145 PSI

Additional Features for Shop Efficiency:

- Auto Indent Sensors: Automatically indent tire beads and release rollers when direction changes, preventing accidental wheel damage.

- Quick Lock Tire Clamping: The patented floating plate mechanism ensures secure clamping for reverse rims, reducing operator effort and setup time.

- Turnkey Design: The R1250 arrives ready to use, minimizing downtime and allowing your shop to service vehicles immediately.

The Rotary R1250 tire changer combines innovative technology and durable construction for unmatched performance, making it the ideal tire changer for high-volume shops. Its lower cost of ownership, economical replacement parts, and fewer moving components ensure long-term reliability and efficiency.

FULLY LEVERLESS OPERATION

SIMPLE, INTUITIVE, PUSH-BUTTON CONSOLE CONTROLS

Reviews

There are no reviews yet.