Rotary® Wheel Aligner – R1090 | Pro 3D Alignment System

Original price was: $39,766.00.$28,130.00Current price is: $28,130.00.

Less of a learning curve to run our software, less space required for the machine in any bay, less total cost involved to start doing alignments yourself. The R1090 Pro 3D is your next alignment system.

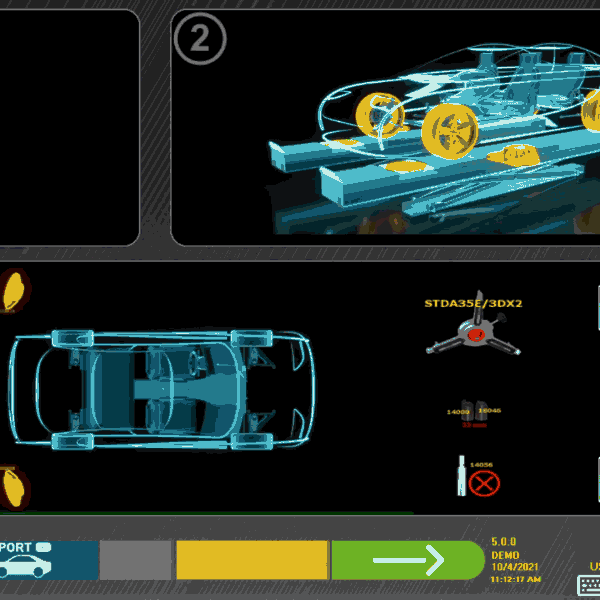

HIGH-PERFORMANCE SYSTEM WITH SOLID VISION TECHNOLOGY

Equipped with fixed cameras, tire grabbing clamps, and remote-controlled sensors.

- Automatic positioning of the cameras

- Automatic recognition of the targets

- ADAS ready

FAST AND EASY SETUP

Console or Tablet Operated System – Includes Android Tablet as a REMOTE indicator

Easy to follow alignment process with updated graphics that feature a time saving On Rack Test Drive Program

- Animated instructions

- Easy to read results

- Adjustment Illustrations

- Live adjustments

- Email or print alignment report

Limited Warranty Statement for Wheel Service Products

All Rotary Wheel Service serialized products are covered under warranty for a period of three years to the original owner.

Important: The warranty period begins on the invoice date to an authorized Distributor, Purchaser, or Account. This date can be adjusted by submitting to VSG Customer Service a Warranty Activation Form indicating the installation date or proof of retail purchase date.

This warranty covers any failure of the serialized product under normal use and service, caused by a defect in VSG material or factory workmanship ("Warrantable Failure"). VSG shall pay for reasonable costs of transportation and labor for replacement of warrantable parts only during the first 12 months of the warranty period.

Warranty for Accessories

Accessories are warranted to the original owner for a period of one year from the retail invoice date. If a retail invoice cannot be produced, the date of the original VSG invoice shall initiate the one-year warranty period.

VSG warrants against defects in material and factory workmanship only. Normal wear and tear of parts is not covered.

Warranty Conditions

- Warrantable Failures: VSG will, at its option, repair or replace any part that has failed due to a defect in material or workmanship.

- VSG may require parts to be returned for inspection to determine warrantability.

- This warranty does not cover:

- Normal maintenance or adjustments, including routine calibrations.

- Damage or malfunction caused by improper handling, installation, abuse, misuse, negligence, or carelessness of operation.

- Force majeure events.

- Unauthorized repairs or alterations.

Warranty Coverage

| Model/Series | Functional Parts** | Labor Warranty |

|---|---|---|

| WHEEL SERVICE | 3 Years | 1 Year |

Exceptions: Calibrations, routine maintenance, and alterations are not covered under warranty.

Exclusions:

- Paint Defects Due to External Influences: Accidental damage, climate, thermal or chemical exposure, industrial pollution, insufficient care or maintenance.

- Air-Powered Items: Damage caused by external fluids or moisture.

Limitation of Liability

This warranty is exclusive of all other expressed or implied warranties, including merchantability or fitness for a particular purpose. The remedies described are exclusive, and VSG shall not be liable for any special, consequential, or incidental damages of any kind, including but not limited to delays or breach of warranty.

This warranty is governed by the laws of the State of Indiana and subject to the exclusive jurisdiction of courts in Jefferson County, Indiana.

Shipping & Delivery Information

Order Processing & Delivery Times

This product ships directly from Rotary. Delivery times vary by product.

After placing your order, it may take up to 10 days to receive an order confirmation and estimated delivery date from the manufacturer.

Once we receive confirmation from the manufacturer, we will email you the estimated delivery date and order confirmation number.

Shipping Disclaimer for Hawaii, Alaska, and U.S. Mainland

- We offer shipping within the United States, including Hawaii and Alaska.

- For Hawaii and Alaska: Shipping is limited to mainland freight distribution centers. Additional costs for ocean freight to Hawaii must be calculated and covered by the purchaser.

- Deliveries to Hawaii and Alaska may take longer than standard U.S. mainland deliveries.

Shipping Costs

Shipping costs will be calculated during checkout.

International Shipping

At this time, we do not offer shipping to international destinations.

Need Help?

If you have any questions or need assistance with your order, please contact us at info@shopequipmentlift.com.