The R1065 Tire Alignment Machine by Rotary is a cutting-edge alignment system, offering precision, convenience, and mobility for professional automotive shops. Operated through a mobile tablet interface, this machine integrates advanced alignment technology to provide accurate measurements and quick, efficient results. With the R1065 wheel alignment machine, technicians can deliver high-quality alignments on a wide variety of vehicles, enhancing productivity and customer satisfaction.

High-Precision Alignment with Advanced Technology

Equipped with sophisticated sensors, the R1065 wheel alignment machine captures precise measurements to ensure accurate alignment for every vehicle. This accuracy reduces uneven tire wear and enhances both handling and safety. As a result, shops can provide alignment services that not only boost vehicle performance but also extend tire life, increasing customer satisfaction and repeat business.

User-Friendly Mobile Tablet Operation

The R1065 wheel alignment machine features a wireless tablet interface, making it easy for technicians to control and monitor the alignment process from any point around the vehicle. With clear, step-by-step instructions, this tablet interface is intuitive for new and experienced technicians alike. Additionally, the mobile control streamlines the workflow, allowing technicians to move freely around the vehicle and reduce time spent on each alignment.

Compact, Portable Design for Maximum Efficiency

Designed for portability, the R1065 wheel alignment machine is compact and easy to maneuver, making it ideal for shops with limited space. Its small footprint allows technicians to set up the machine wherever it’s needed, maximizing shop efficiency. Moreover, the R1065’s mobility enables shops to handle more vehicles in less time, increasing service capacity without the need for additional space.

Versatile Applications for a Range of Vehicles

The R1065 wheel alignment machine is compatible with a variety of vehicle types, from compact cars to SUVs and light trucks. This versatility allows shops to meet diverse customer needs with one machine, expanding service options. By using the R1065, technicians can adapt to different vehicle requirements quickly, improving both customer satisfaction and shop reputation.

Boost Shop Productivity with the R1065 Wheel Aligner Machine

For shops seeking a reliable, mobile alignment solution, the R1065 Wheel Alignment Machine by Rotary is an invaluable addition. Its advanced alignment technology, intuitive tablet control, and portable design make it perfect for delivering efficient, high-quality alignment services. Equip your team with the R1065 to enhance productivity, reduce alignment time, and provide outstanding service to every customer.

ADDITIONAL FEATURES:

- Advanced WIFI communication technology between TABLET and CCD Sensors

- Infra-red transmission between measuring heads

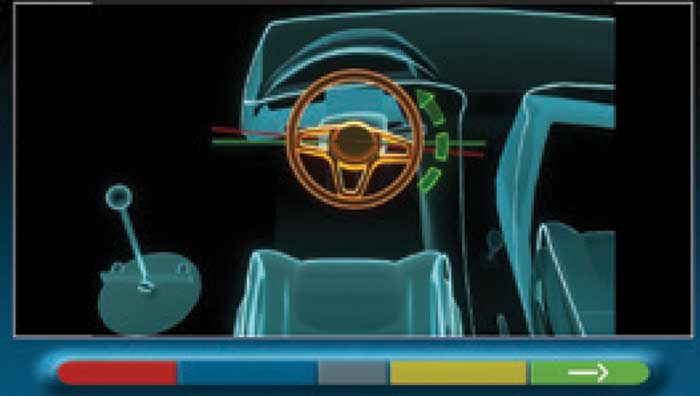

- Alignment & adjustment software guided by 3D images

- Set of 4 STDA33EU four point clamps, for 8” to 24” rims

- Encoder in sensor to speed the Run Out Process

- Print to WIFI Printer (Not included) or email test results directly to the customer

STANDARD EQUIPMENT INCLUDES:

- Brake pedal depressor

- Steering wheel holder

- Mobile cart with 10″ tablet

- Automatic battery charger

- 2 front measuring heads

- 2 rear measuring heads

SPECIFICATIONS:

| R1065 Alignment System Technical Data | Accuracy | Measuring Range | Total Measuring Range |

| Front axle | |||

| Total toe | + / – 3’ | + / – 2˚ | + / – 20˚ |

| Partial toe | + / – 1’ 30” | + / – 1˚ | + / – 20˚ |

| Set-back | + / – 2’ | + / – 2˚ | + / – 5˚ |

| Camber | + / – 2’ | + / – 3˚ | + / – 10˚ |

| Caster | + / – 5’ | + / – 10˚ | + / – 18˚ |

| King-pin | + / – 5’ | + / – 10˚ | + / – 18˚ |

| Rear axle | |||

| Total toe | + / – 3’ | + / – 2˚ | + / – 20˚ |

| Partial toe | + / – 1’ 30” | + / – 1˚ | + / – 20˚ |

| Set-back | + / – 2’ | + / – 2˚ | + / – 5˚ |

| Camber | + / – 2’ | + / – 3˚ | + / – 10˚ |

| Thrust angle | + / – 2’ | + / – 2˚ | + / – 5˚ |

| Power supply | 110v / 1Ø / 60 Hz | ||

UPDATED ANIMATED INSTRUCTIONS AND GRAPHICS GUIDE THE ALIGNMENT PROCESS

Includes Spoiler Program for lowered vehicles – automatically activated to measure sport and tuned car bodies.

Technical Vehicle Data

3D Run Out Info

Animated Adjustments

Easy Alignment Display

Reviews

There are no reviews yet.